A vehicle’s fuel system is a critical component that ensures the engine receives the right amount of fuel at the right time. When issues arise within the fuel system, it can lead to poor performance, reduced fuel efficiency, and even engine damage. In this essential guide, we’ll explore the techniques, tips, and best practices for effective fuel system repair.

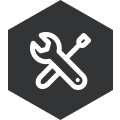

Understanding the Fuel System Components

Before jumping into repair techniques, it’s crucial to understand the key components of a fuel system. These include:

- Fuel tank: Stores the vehicle’s fuel supply

- Fuel pump: Transfers fuel from the tank to the engine

- Fuel filter: Removes contaminants from the fuel

- Fuel injectors: Spray fuel into the engine’s combustion chamber

- Fuel pressure regulator: Maintains consistent fuel pressure

Familiarizing yourself with these components and their functions will help you diagnose and address fuel system issues more effectively.

Common Fuel System Problems

Several common issues can arise within a fuel system, including:

- Clogged fuel filter: Restricts fuel flow, causing poor performance

- Faulty fuel pump: Leads to insufficient fuel delivery and engine stalling

- Dirty or clogged fuel injectors: Results in uneven fuel spray and rough engine performance

- Leaking fuel lines: Cause fuel loss and potential fire hazards

- Malfunctioning fuel pressure regulator: Leads to inconsistent fuel pressure and engine performance issues

Recognizing these problems and their symptoms is the first step in effective fuel system repair.

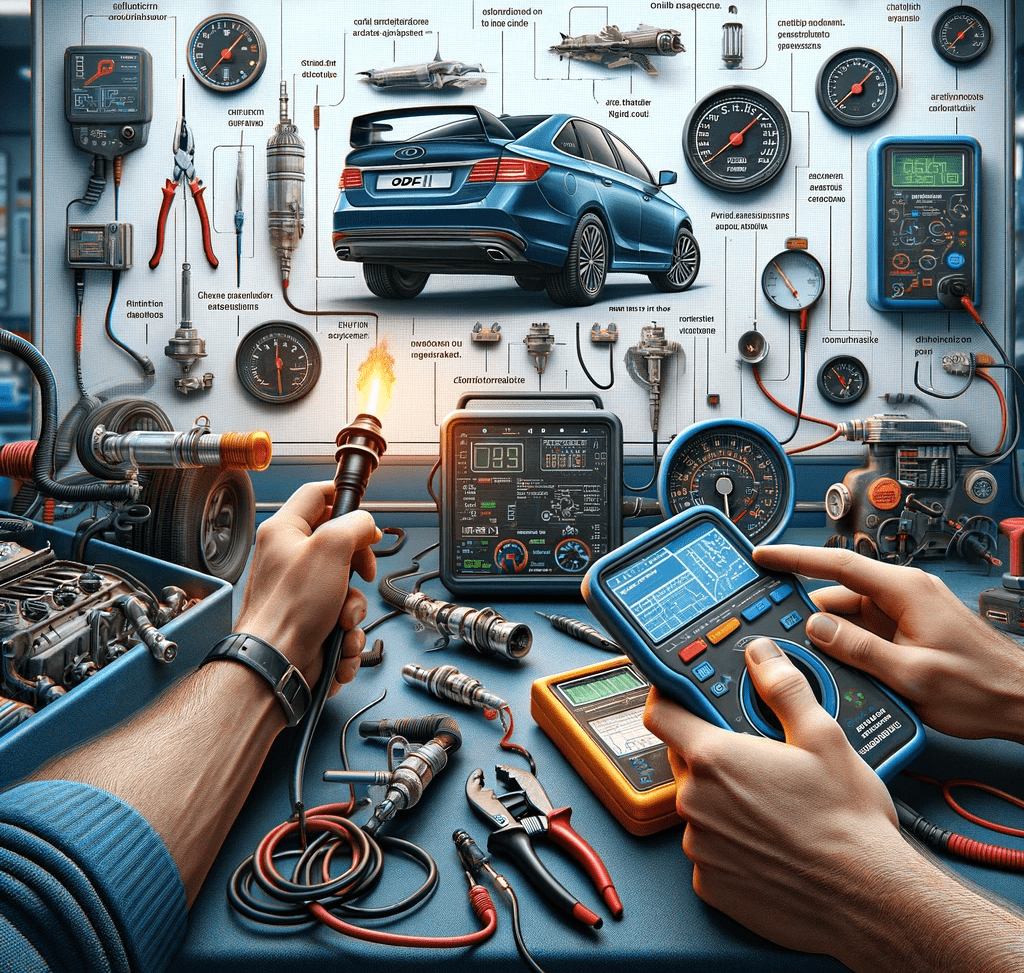

Diagnostic Techniques

When troubleshooting fuel system issues, employ the following diagnostic techniques:

- Fuel pressure test: Use a fuel pressure gauge to measure the system’s pressure and identify any deviations from the manufacturer’s specifications.

- Fuel flow test: Measure the volume of fuel flowing through the system to detect restrictions or blockages.

- Injector resistance test: Check the electrical resistance of the fuel injectors to identify any malfunctioning units.

- Visual inspection: Examine fuel lines, hoses, and connections for signs of leaks, cracks, or damage.

These diagnostic techniques will help you pinpoint the root cause of fuel system problems and guide your repair efforts.

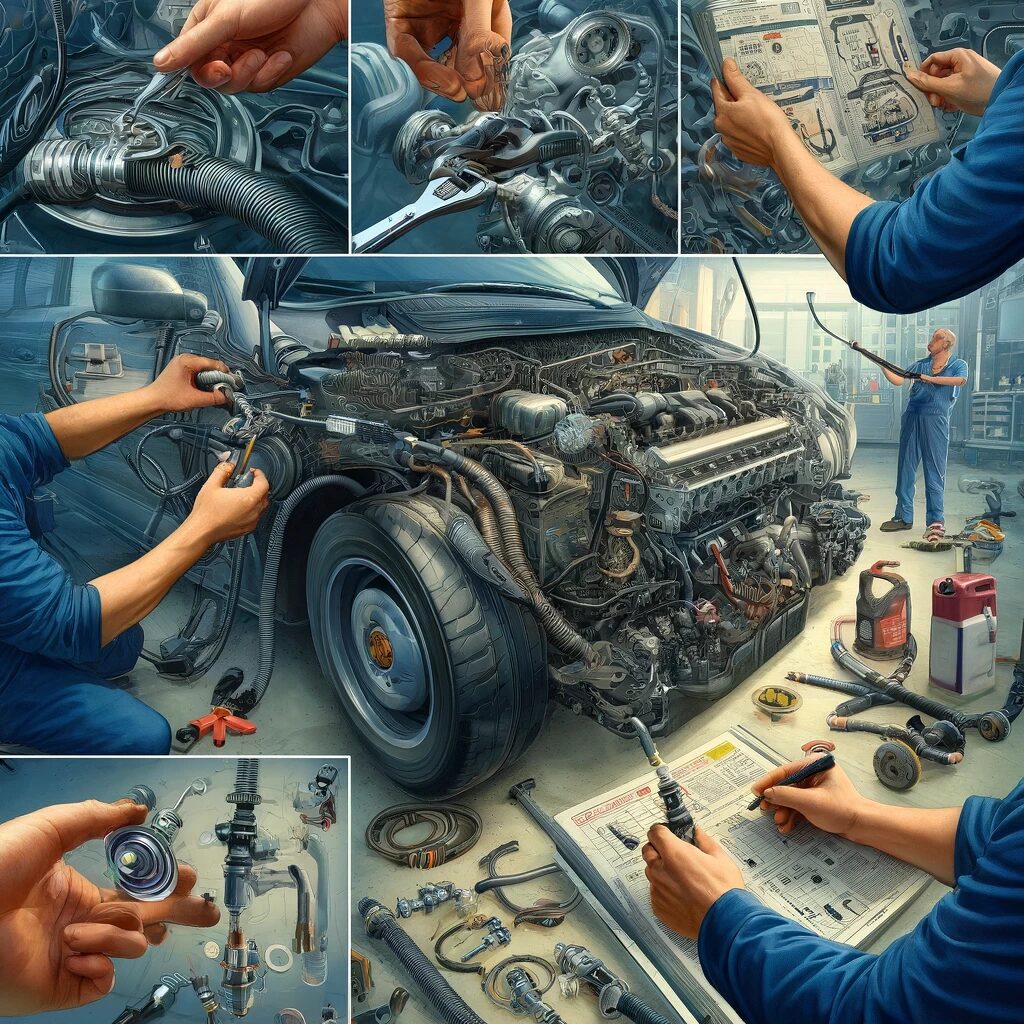

Repair Techniques and Best Practices

When repairing fuel system components, adhere to the following techniques and best practices:

-

Fuel filter replacement:

- Use the correct filter for your vehicle make and model

- Ensure proper installation to prevent leaks or damage

- Replace the filter at the manufacturer’s recommended intervals

-

Fuel pump replacement:

- Choose a high-quality replacement pump that meets OEM specifications

- Properly prime the new pump before installation

- Ensure secure electrical connections and proper mounting

-

Fuel injector cleaning and replacement:

- Use a professional-grade injector cleaning kit to remove deposits

- Replace severely clogged or damaged injectors with new units

- Ensure proper injector alignment and sealing during installation

-

Fuel line repair and replacement:

- Inspect fuel lines for kinks, cracks, or leaks

- Replace damaged lines with high-quality, OEM-equivalent components

- Use proper flaring techniques and fittings to ensure secure connections

-

Fuel pressure regulator replacement:

- Choose a regulator that matches the vehicle’s specifications

- Ensure proper installation and secure connections

- Verify correct fuel pressure after replacement

By following these repair techniques and best practices, you can ensure lasting and reliable fuel system repairs.

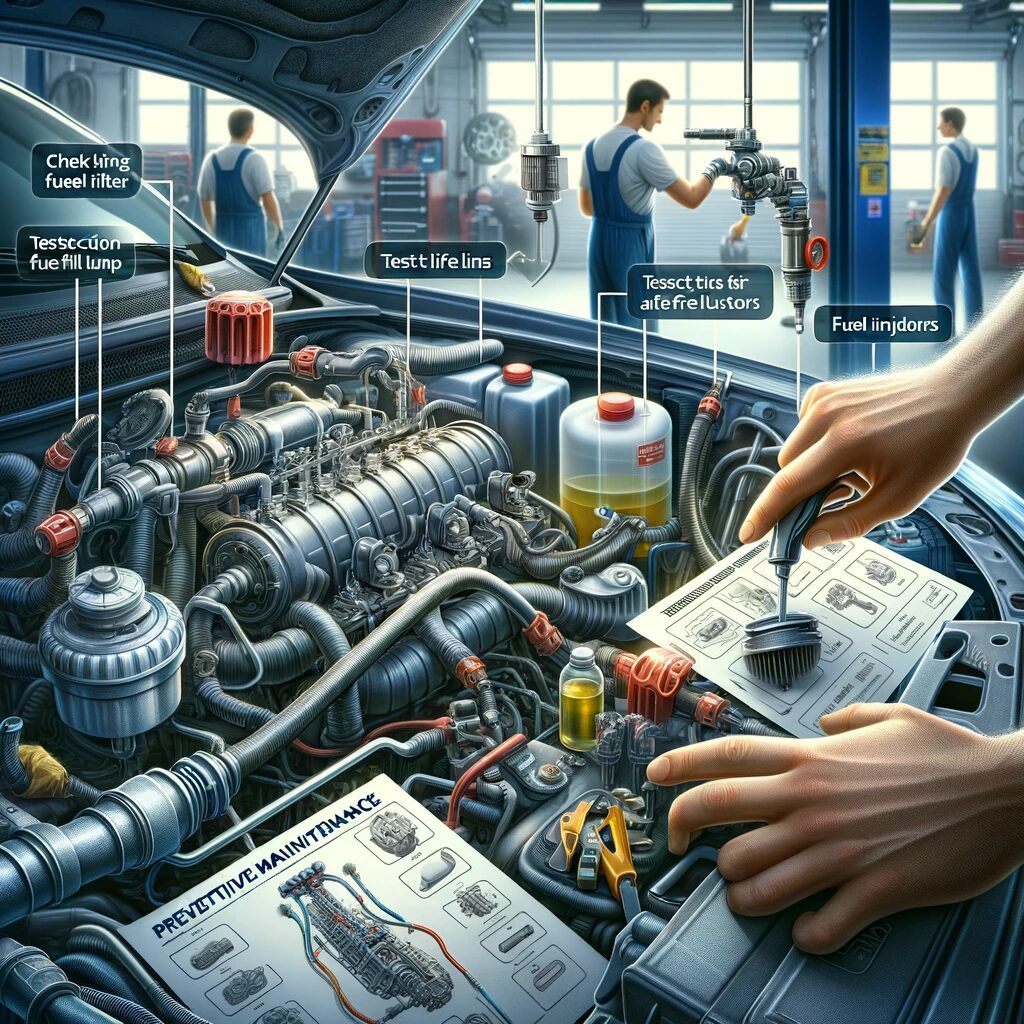

Preventive Maintenance

Regular preventive maintenance is key to keeping your vehicle’s fuel system in optimal condition. Follow these tips to minimize the risk of fuel system issues:

- Use high-quality fuel from reputable sources

- Regularly replace the fuel filter according to the manufacturer’s recommendations

- Keep the fuel tank at least one-quarter full to prevent pump damage and sediment buildup

- Address any fuel system issues promptly to prevent further damage

- Perform regular engine tune-ups to maintain overall vehicle health

By incorporating these preventive maintenance practices into your vehicle care routine, you can extend the life of your fuel system and prevent costly repairs.

Safety Considerations

When working on a vehicle’s fuel system, prioritize safety by following these guidelines:

- Always disconnect the battery before beginning any fuel system repairs

- Work in a well-ventilated area to avoid inhaling fuel fumes

- Wear protective gloves and eyewear to prevent contact with fuel and debris

- Keep a fire extinguisher nearby in case of any sparks or ignition sources

- Properly dispose of any old fuel or components in accordance with local regulations

By adhering to these safety considerations, you can minimize the risk of injury or damage while performing fuel system repairs.

Conclusion

Fuel system repair is a critical aspect of vehicle maintenance that requires knowledge, skill, and attention to detail. By understanding the components, common problems, and diagnostic techniques, you can effectively troubleshoot and repair fuel system issues. Adhering to best practices, prioritizing preventive maintenance, and following safety guidelines will ensure lasting and reliable repairs.

Remember, if you are unsure about any aspect of fuel system repair or lack the necessary tools and expertise, it’s always best to consult with a professional mechanic. By staying proactive and addressing fuel system issues promptly, you can keep your vehicle running smoothly and efficiently for years to come.

Trust Metric Motors for Expert Fuel System Repair

We understand the importance of getting you back on the road quickly, which is why we use only the highest-quality replacement parts and provide prompt, reliable service. As one of Northern Colorado’s premier auto repair shops, we take pride in delivering exceptional results to keep your vehicle in top condition.

Don’t let fuel system problems lead to costly repairs down the line. Trust Metric Motors to address your concerns and provide the expert fuel system repair you need. Take advantage of our special offers to make your auto repair experience even more affordable.

Contact Metric Motors today to schedule an appointment with our skilled mechanics. Let us keep your fuel system working at its best, so you can focus on the journey ahead.

FAQ Section:

1: What are the main components of a vehicle’s fuel system?

The key components include the fuel tank, fuel pump, fuel filter, fuel injectors, and fuel pressure regulator.

2: What are common fuel system problems?

Common issues include a clogged fuel filter, faulty fuel pump, dirty or clogged fuel injectors, leaking fuel lines, and a malfunctioning fuel pressure regulator.

3: How can I diagnose fuel system issues?

Diagnostic techniques include performing a fuel pressure test, fuel flow test, injector resistance test, and visual inspection of fuel lines and connections.

4: What is the importance of replacing the fuel filter regularly?

Regular replacement of the fuel filter ensures that contaminants are removed from the fuel, maintaining optimal fuel flow and engine performance.

5: How do I properly replace a fuel pump?

Choose a high-quality replacement pump, prime the new pump before installation, and ensure secure electrical connections and proper mounting.